Dairy cattle cooling system

May 3, 2022HEAT STRESS

The optimal temperature range for dairy cows is between 4° and 16°C rising summer temperatures cause heat stress on cows (symptoms: e. g. increased standing; rapid shallow breathing > 80/min; body temperature > 39°C; the animals accumulate at better ventilated spots.

Problems from heat stress:

- Stress on metabolism

- Lower feed intake,

- Reduced fertility and lower milk yield

- More standing

- More load on the claws

- Increased risk of lying damage through sweating and softening of the skin

heat stress starts at 24°C; above 27°C there are significant reductions in yield

- Air temperature and relative humidity must always be evaluated together: the cow generates not only heat but also water vapors (15 l water per day at -1 °C and 30 l per day at 26 °C)

- the higher the humidity, the more cows react to heat stress, especially the high yield ones

- humidity should not be over 70%, which means that high air change rates (60 to 100 times per h) are required!

Keep in mind with non-insulated stables

- Non-insulated roof: Additional heat influx 165 – 990 W per cow possible!

- Lower temperature difference outside/inside:

- The air can absorb less water vapors

- Higher air change rates required (in winter, too)

Water cooling only up to 70 % rel. humidity, therefore humidity sensors are important!

TIP

- Maximize water availability

- Optimize feeding management

- Feeding more often and at cooler times of the day

- Supporting ventilation

- Dissipates heat and humidity:

- Required at air speeds < 1 m/s

- highest cooling effect at 2.5 m/s air speed; harmless up to 5 m/s

- Rule of thumb for ventilators: per 10 cm diameter 1 m range, common sizes: 12 – 15 m range, in twin block: 18 – 20 m

- Water cooling (source: DLG-Merkblatt 336 [explanatory leaflet])

- High pressure misting is Principle “air cooling” technically difficult because of fine nozzles per 1°C cooling, relative humidity increases by 5%!

- Low pressure atomizing principle “soak the hide, cool the animals through evaporation”: technically easier, e.g., horticultural irrigation systems are utilizable only at temperatures > 24°C

- 15 min intervals (3 min water spraying, 12 min for evaporation)

- 1 l water/m² (and 3 min spraying)

Barn and animal cooling system

Animal Cooling systems

In order for animals to cope with heat stress (thermal), it is necessary to cool the living environment (barn) and/or the animal itself. Methods and models that can be applied to barns and animal cooling systems. Will we cool the animal or the barn? Combating heat stress in dairy cattle (thermal).

Cooling system in barn recommended in barn stall or and milking parlor. It is depending on how you user your barn and what kind of housing system used for animal keeping

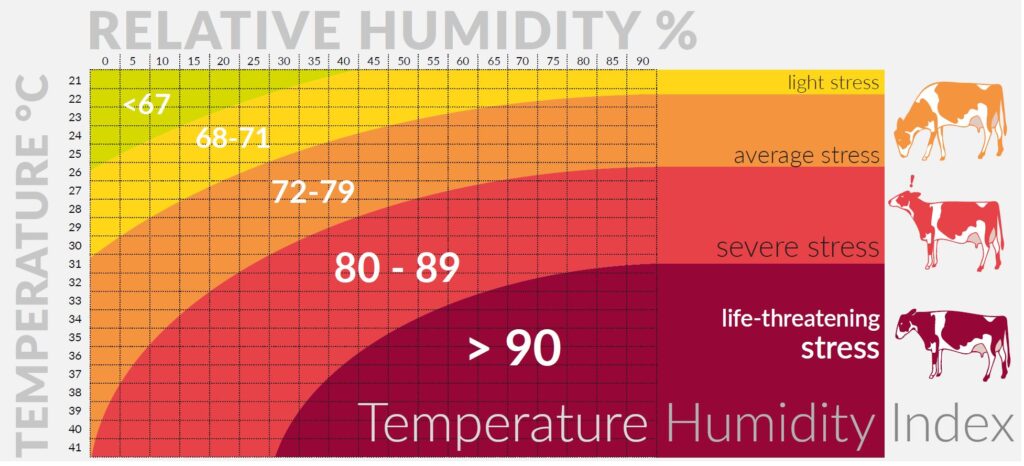

Temperature-Humidity Index

Like humans, animals are also affected by meteorological factors, especially if they are damaged by extreme heat and humidity. With the effect of global warming, which has been felt more in recent years, heat stress has a distinct effect on dairy cattle and causes significant milk losses.

Different indices are used to determine the level of heat stress in dairy cattle. These indexes are generally called “Temperature-Humidity Index” (SNI or THI). By looking at the calculated index value, the heat stress level that dairy cattle are exposed to and how much of a decrease in milk production can be estimated.

The “Temperature-Humidity Index Program (SINEP)” has been prepared in order to predict the time periods during which heat-humidity stress may occur, which causes significant yield losses in cattle breeding in our country, as it is all over the world, thus enabling our farmers to take the necessary precautions and minimizing their losses.

In this program, stress values are calculated by applying hourly temperature and humidity forecast values produced by the Weather Forecasting and Research Model (WRF) to the most appropriate Temperature-Humidity Index determined for our country.

Stress intensities and color columns are created according to the stress values. Thus, our producers will be able to take the necessary precautions and plan by seeing the time zones and stress intensities in which their animals may be stressed 72 hours in advance.

THI value used

THI = (1.8 × T + 32) – [(0.55 – 0.0055 × RH) × (1.8 × T – 26.8)] (NRC, 1971).

Here, T is the air temperature in °C and RH is the relative humidity in %. The value in question is classified as

- no stress when it is less than 66,

- mild stress between 66 and 71,

- STRESS between 72 and 79,

- intense stress when it is between 80 and 89,

- and extreme stress when it is 90 and above.

In many countries’ climatic conditions, many methods are used to protect from heat stress, which causes significant losses in milk production, especially in our southern and western regions.

With many modern methods such as shading, ventilation, irrigation-wetting, providing cold drinking water, scientific feeding strategies, the decrease in milk yield can be prevented by alleviating or completely removing the temperature (thermal) stress in dairy cattle.

It will be more economical and more profitable and sustainable animal husbandry activities will be carried out by preventing the decrease in milk yield, if these cooling and stress protection methods, which are obligatory in terms of aquaculture, are planned in advance and applied correctly and on time.

Whether it is a family type business or a milk production facility in modern livestock facilities, it is of great importance to know the time periods in which animals will be exposed to stress in daily planning.

As an Agricultural Meteorological application, the Temperature-Humidity Index Calculation Program (SINEP) has been designed for livestock activities in our Turkey.

The program has been prepared in a simple and understandable way, which can be used by a wide audience, from farmers to researchers.

Evaporative cooling systems

Ventilation systems and circulation fans that provide good air exchange are important to reduce the moisture load in the air, as it involves adding water to the animals’ ambient air.

Evaporative cooling

Uses water to increase heat transfer from cows. Evaporation of one pound (or pint) of water requires about 1,000 British thermal units (BTUs) of energy, about as much as the heat produced by 1,000 four-inch wooden matches.

Direct evaporative cooling

(DEC) systems intermittently evaporate the water they apply to the cow leather and draw heat directly from its body. Indirect evaporative cooling (IEC), on the other hand, increases the heat transfer rate by lowering the temperature of the ambient air surrounding the cow.

Indirect evaporative cooling (IEC)

By using the heat in the air, it takes the moisture from the air that evaporates from the hot air and lowers the air temperature. The heat transfer rate increases when the temperature difference between the cow’s body and the surrounding air increases. As cows breathe cooler air, heat transfer increases through the body.

Fogging and misting

Very High-pressure systems with Semi-Dry Hi-Tech nozzles emit better droplets from nozzles that emit small droplets with a better chance of evaporation before they settle on the cow’s hair skin, surface and ground Pressurized IEC systems are used in arid climates where droplets are more likely to evaporate suspended in the air and are desired to stay dry for floors.

Evaporative pads

IEC is another method. Thick, water-soaked corrugated pads are placed at the entrance openings used with tunnel and cross-ventilation systems. Pad. The outside air drawn through it lowers the dry (bulb) thermometer temperature, evaporating as much moisture as weather conditions allow. All air drawn from the inlet is cooled and can only absorb as much moisture as weather conditions allow.

Spray cooling systems

They are low pressure DEC systems installed in supply and holding areas using a 5 – 15-minute wet-dry cycle. The spray nozzles emit a coarse droplet that penetrates the cow’s bristle skin by soaking the cow for 1-3 minutes. Fans provide the necessary air movement to accelerate evaporation and remove heat from their bodies, which seems to be the most effective method of evaporative cooling for cows in humid climates However, it may require a significant water supply and good drainage link for details https://www.youtube.com/embed/3lADaq39zpU?feature=oembed

Wet and semi-dry cooling systems

The difference between the wet and semi-dry system for barn and animal cooling is related to the amount and amount of water droplets given to the environment on the animal. In semi-dry systems, the amount of water sprayed with nozzles is very low. While the number of drops and the amount of heat capture (average 6 ºC) increase, it significantly reduces the amount of water on the ground and the animal. (Classification of droplets)

Note the drops: these must have a large diameter and should not be sprayed; condensation can increase the humidity level in the air and worsen thermal stress.

linear suspended water sprinkler line

1 “1/4” stainless steel pipe, every 2.1 m and 170 and 360° nozzles spraying nozzle solenoid valve, filter, drain excluding intermediate and gaps and outlets. CEDO Remote control panel. Run timer for ventilation management and reduces fan speed during soaking.

I have read several good stuff here. Certainly worth bookmarking for revisiting. I wonder how much effort you put to create such a wonderful informative web site.