Description

Peripheral Centrifugal Water Pumps 2.6 m3 /hours

Peripheral Water pumps are generally known as friction fan pumps, because the pump impeller provides pressure by rubbing against a surface. Pump impellers and friction surfaces are generally made of stainless or bronze materials. Peripheral centrifugal pumps with power between 0.50 – 1.5 HP, the pump systems.

These pumps are used to supply clean water in residential areas, industrial facilities, irrigation applications, places requiring high temperature and pressure such as ironing machines and steam boilers, heating-cooling systems, yacht and shipping industry, small gardens, villas and summer houses in small diameter gardens, in villas and cottages. For irrigation, household use, or livestock farming, having the right type of water pump is essential. Different types of water pumps available in Kenya.

One type of surface water pump commonly used in Kenya is the centrifugal pump. This type of pump uses rotating impellers to create pressure and move large volumes of water quickly. Centrifugal pumps are efficient and easy to operate, making them a popular choice for agricultural irrigation and other applications that require high flow rates.

Peripheral water pump systems

Due to the fact that the impeller and friction surfaces of the water pump are bronze, Peripheral water pumps are suitable for use in places that require high temperature and pressure, in small-scale gardens, pump systems, pump technologies, and clean water supply to distant places. These are the main booster pumps, garment ironing machine pump, textile steam ironing pump, pressurization pump, hydromatic pump suitable for practical use, and our water pumps, which are suitable for use as a hot water pump, can also be manufactured as a special hot water pump.

- Peripheral water pump systems, pump technologies, water pumps that suck from a depth of 6 meters are water pumps with a minimum head of 40 m and a maximum head of up to 103 m.

- The water pump has the ability to make suction, even if the impeller is in the form of a star, they are in a position to suck because the friction fan works with a power between 0.50 – 1.5 HP and are suitable for use in many different areas.

- These pump series MS 5-10-15 are manufactured at frequencies of 50 Hz and 60 Hz. USAGE AREAS and maximum 2.6 m3 /hours

Selection of Peripheral water pumps

Regarding the selection of Peripheral pumps it should be known , Friction Fan Centrifugal pumps, as the name suggests, are pumps that flood water with centrifugal effect. Friction Fan Pumps are machines that increase the energy or pressure of liquids. In this regard, pumps are used to send a liquid from low to high or from low pressure to high pressure. On the other hand, pumps are also used to increase the flow rate and thus the flow rate of the liquid flowing in a pipe.

How it works

If we talk to centrifugal pumps, in these pumps, which consist of a vane impeller in a body, the liquid enters the pump through a suction pipe.

The path of the liquid in the suction water pump is as follows. Due to the vacuum created on the suction side of the impeller, the liquid enters between the blades of the impeller.

Regarding the installation of Peripheral pumps The fluid passing between the impeller blades gains a great tangential velocity with the rotational movements of the impeller. Between the impeller blades and the channels bounded by the front and rear profiles of the impeller, the liquid is pushed towards the exit side of the impeller by the centrifugal force that occurs during the rotational movement.

The movement created in this way ensures the continuous flow of liquid and suction from the suction side of the pump.

The kinetic energy contained in the liquid leaving the impeller blades with a great tangential velocity is converted into a pressure force in the volute cavity between the fixed diffuser blades. The highest pressure is achieved with a given rotational speed. This kind of pump can be said to be a hydrodynamic pump.

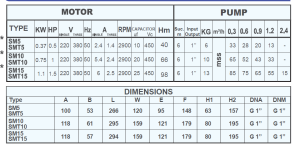

Water PUMP TECHNICAL SPECIFICATIONS

MONOPHASE MODELS HAVE THERMAL PROTECTION AGAINST OVERLOADS.

| Pump Body | GG25 Iron casting CAST IRON IMPELLER |

| Wheel | Bronze SHAFT |

| Shaft | AISI 304 INOX |

| Flow (max) | 2.6 m3 /hours |

| Discharge TOTAL HEAD | 98 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Cable Length | 10 m |

| Mechanical Seal | SEAL CERAMIC/ CARBON |

| PUMP DURABILITY PRESSURE (Pmax) | 10 bar |

Optionally, it can be manufactured to be used in hot water applications up to 90 °C.

QUALITY CERTIFICATIONS

TSE certificate. Pumps are designed and manufactured in accordance with TS EN ISO 9908 standard. In the electric motor windings, F insulation class cables are used in accordance with TS 60085:2011. Motor safety are prioritized by using a 2-pole asynchronous motor with IP 54 protection class in accordance with TS 3033 EN 60529.

Reviews

There are no reviews yet.